Our Services

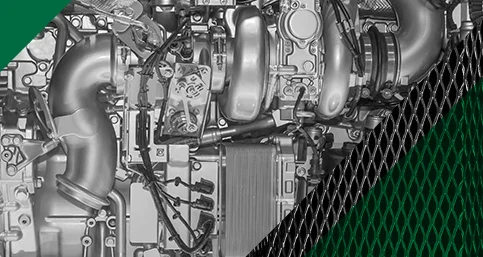

We offer a wide variety of services for your heavy machinery. We specialize in engine block machining services, honing, align honing, crack repairs, engine borescoping and engine failure analysis. We offer both shop services and field services.

Our Shop Services

Honing and align honing

Common failures in most big machinery include bearing wear, spun bearings, excess crack wear, cracks or breaks in the crank, block or main caps. These can be fixed by making sure bores are straight and at the proper specs for diameter and shape. Machine operation can be used to correct any further defects.

Engine Compression Solutions offers honing services, which can correct any small discrepancies, as well as ensure good, round, properly-sized main bores that are all aligned on the same centreline. Our technicians hone the bores in short steps so that all the bores can be measured after each cut, allowing for adjustment as needed throughout the process.

A loose main cap can exaggerate the problem of crank stability and can mean early engine failure. By regular maintenance and check-ups, you can avoid catastrophic repairs down the road.

Crack Repairs

There are multiple methods of repairing cracks in cast metal without welding, including metal stitching, where metal stitching pins are used to replace the crack itself, or by using metal locks. Metal locks offer superior functionality and are exceptionally versatile:

- Speed: They can be done quickly with pneumatic tools.

- Ease of use: They are designed with a break-off groove that causes each pin to break off at the same predetermined torque.

- Flawless finish: All pins have shoulders that set into the casting so the threads aren't exposed at the surface.

- High pressure seal: Uniformed repair seals without the use of epoxies or coatings.

- Holding power: They create strength and seal every linear inch of the repair.

- Complex contours: As easy to fit as flat surfaces.

Engine Failure Analysis

At Engine Compression Solutions, we know diesel engines are expensive to replace or rebuild. You want someone who understands the complexity of their unique set of conditions, effects and situations including how each engine component is designed and manufactured, how they function and how they interact with other engine components.

When analyzing engine failure, all clearances, conditions of components, operation and services of the vehicle must be taken into consideration. With our team's accumulated and intimate knowledge of every engine type, we apply this expertise to determine the best way to fix your machine, and suggest ways to prevent further engine failure in the future.

Our breadth of experience is vast, and we can offer you repair and analysis of the following common causes for engine failure:

- Melted pistons

- Hole in pistons

- Dusting

- Bent connecting rods

- Hole in block

Consulting

Starting up a company and need some expert advice on what machines will guarantee a return on your investment? Looking to replace older machines and need some guidance as to what new technologies are available, and what they can do to keep your company going strong?

Our skilled and knowledgeable staff is always happy to share their insights and give you sound recommendations that you can trust. Contact us today for a free consultation – at Engine Compression Solutions, we're the second opinion you should have asked for first!

Our Field Services

Field engine machining

Your time is valuable – that's why Engine Compression Solutions offers field services. Our expert machinists will come to you in order to meet your tight timelines and budget requirements. We reduce customer downtime with our specialized mobile equipment to perform work in hours or days, rather than weeks or months.

All of our field service technicians have technical knowledge of rigging, machine setup, alignment and machining processes, and our quality workmanship and on-time delivery always comes with competitive prices.

Engine block machining services

We offer the highest quality engine block machining services, which are always inspected and measured against OEM specifications by our skilled technicians on-site before we leave. We provide all machining services, including:

- Upper and lower bore replacement

- Main bearing align boring, align hone and sleeving

- Cam tunnel bore align boring, align hone and sleeving

- Cylinder re-boring, honing and sleeving

- Mating deck resurfacing

- Spray welding and fitting of main caps

- Crack and damage repair

- Cam bearing removal and installation

- Pressure testing

Engine borescoping

Engine Compression Solutions knows that your diesel engine is more powerful than most gasoline engines, but it's also more susceptible to piston failure. We offer engine borescoping to inspect your engine without the hassle and expense of having to transport it to a shop, or completely disassemble the entire engine. Our mobile borescope can find defects often undetectable by a compression check (i.e., glazing or scoring of the cylinder walls, corrosion of the cylinder itself, cracks, conditions like piston ring damage and evidence of excessive blow-by).